Washbacks - Traditional plant with German high-tech

Traditional washbacks with German high-tech

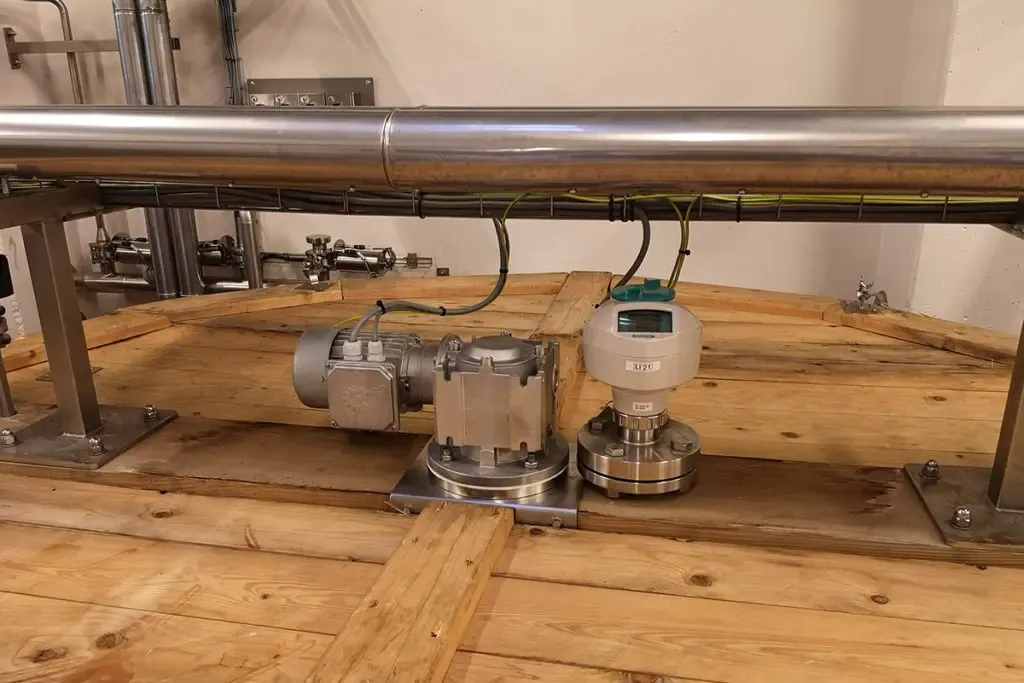

Our new floor agitators

We continue to invest in our unique production facility. From the beginning, we are linking our traditionally Scottish facility with German high-tech.

In this case we decided to upgrade our wooden washbacks from J.B. Vatts in Dufftown Scotland made from Oregon Pine with foam beaters from above and bottom agitators from below.

Due to the CO2 produced by the yeast during fermentation (in addition to alcohol and heat), foam is produced, especially in the main fermentation phase. So far, we have kept this foam at bay by adding a little fat. The fat does not allow foam to form in the first place. Since it cannot be overdistilled, it remains in the spent wash (the stillage) later.

Our aim is now to do without the fat and to keep the foam down by means of mechanical breaking or cutting. This means that no more grease is used. In addition, the cleaning work in the washbacks is made much easier. Finally, fat no longer comes into contact with yeast during fermentation. Improved fermentation is the goal here.

Both types of foam suppression are also practised in Scotland. Partly also by adding soap instead of fat.

New foam beaters for improved fermentation

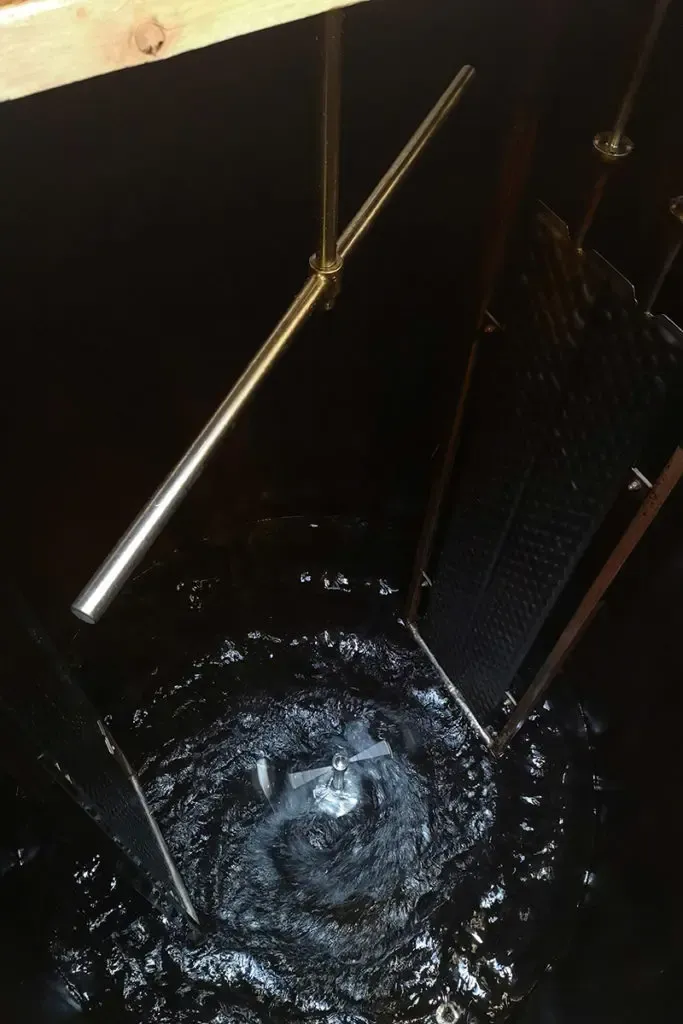

The new bottom agitators ensure better homogeneity and thus better distribution of the yeast in the fermentation vat. They are designed to rotate very gently and slowly. This minimises the shear forces on the wash and on the yeast. At the same time, the best possible contact of the yeast with the sugar to be fermented is our concern. This improves fermentation and increases the yield.

Since we distil a washback twice raw in our washstill, the agitator also ensures two equal parts of wash here. This is very important to us later to maintain the quantity and alcohol balance between low wines, spirit, foreshots and feints.

Right from the start we had two stainless steel cooling plates (unusual in Scotland) installed in each washback to maintain the perfect fermentation temperature. This way, the yeast produces the best flavours for us.

So we give everything for the best result and the highest possible quality.